- Products & Services

Products & Services

Core Offerings

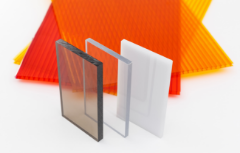

Materials

Product Brands

- Industry

- Catalog

- Where to Buy

-

What's New

Michael Gilbert named President & CEO

Industry veteran selected to lead Plaskolite

Our mission is to produce innovative engineering thermoplastics

the right way

Sustainability

Creating sustainable products, in a responsible manner, for future generations.

.png?sfvrsn=f93e0974_2)