- Products & Services

Products & Services

Core Offerings

Materials

Product Brands

- Industry

- Catalog

- Where to Buy

-

DURAPLEX® Impact Modified Acrylic

DURAPLEX® Impact Modified Acrylic

DURAPLEX continuously-processed, impact-modified acrylic sheet is up to 30 times stronger than double-strength window glass and 50 times stronger than polished wire glass or other glasses, making it an excellent choice for displays, skylights, signage and replacement windows. DURAPLEX is available in custom impact blends and a range of thicknesses, widths, colors and patterns and in flat sheets or roll stock.

Run-to-Size Capabilities

- THICKNESS 0.040" – 0.500"

- WIDTH 5" – 105"

- LENGTH 14" – 216"

- Indoor

- Outdoor

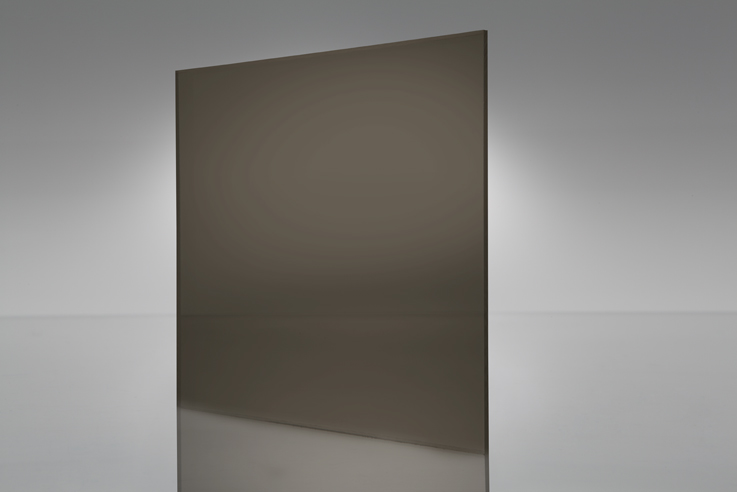

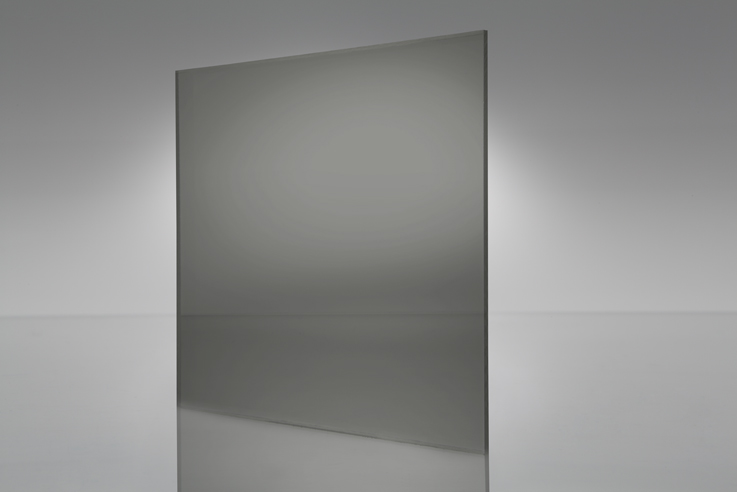

Available Colors

View More +

View Less —

Custom colors available.

**Colors on screen may not reflect exact matches to physical sheets.

*Non-Stock colors, patterns or sizes may require a minimum quantity order.

Features & Benefits

View More +

View Less —

40% impact modified acrylic is 5 to 6 times stronger than general purpose acrylic, 10 to 15 times stronger than double strength window glass, and 20 to 30 times stronger than polished wire glass or other glasses

100% impact modified acrylic is 10 times stronger than general purpose acrylic, approximately 20 to 30 times stronger than double strength window glass, approximately 40 to 50 times stronger than polished wire glass or other glasses

Thicknesses .040"–.500"; widths up to 105"

Offered in clear, colors, patterns, and Run-To-Size

| REQUEST | ITEM # | COLORS | PATTERN/TEXTURES | MASKING | THICKNESS (in.) | SIZE (in.) | SQ FT | PACK QTY | SKID QTY |

|---|---|---|---|---|---|---|---|---|---|

| 1X08123A | Clear | 40% Impact Modified | Polyfilm - Clear/Polyfilm - White | .080 | 18” x 24” | 3 | 10 | ||

| 1X08126A | Clear | 40% Impact Modified | Polyfilm - Clear/Polyfilm - White | .080 | 30” x 60” | 12.500 | 5 | ||

| 1X08127A | Clear | 40% Impact Modified | Polyfilm - Clear/Polyfilm - White | .080 | 24” x 48” | 8 | 6 | ||

| 1X02448A | Clear | 40% Impact Modified | Polyfilm - Clear/Polyfilm - White | .093 | 24” x 48” | 8 | 10 | ||

| 1X02830A | Clear | 40% Impact Modified | Polyfilm - Clear/Polyfilm - White | .093 | 28” x 30” | 5.833 | 10 | ||

| 1X03244A | Clear | 40% Impact Modified | Polyfilm - Clear/Polyfilm - White | .093 | 32” x 44” | 9.778 | 10 | ||

| 1X08105A | Clear | 40% Impact Modified | Polyfilm - Clear/Polyfilm - White | .093 | 8” x 10” | .556 | 5 | ||

| 1X47435A | Clear | 70% Impact Modified | Polyfilm - Clear/Polyfilm - White | .118 | 48” x 96” | 32 | 5 | ||

| 1X47433A | Clear | 70% Impact Modified | Polyfilm - Clear/Polyfilm - White | .177 | 48” x 96” | 32 | 3 |

Physical |

TEST METHOD |

UNITS |

DURAPLEX 30% |

DURAPLEX 70% |

DURAPLEX OPTIX SG05 (50%) |

DURAPLEX OPTIX SG10 (100%) |

|---|---|---|---|---|---|---|

Specific Gravity/Relative Density |

ASTM D792 |

1.18 |

1.16 |

1.17 |

1.15 |

|

Light Transmission -Total |

ASTM D1003 |

% |

92 |

90 |

92 |

90 |

Light Transmission - Haze |

ASTM D1003 |

% |

2 |

>3 |

2 |

>3 |

Water Absorption |

ASTM D570 |

% |

0.3 |

0.3 |

0.3 |

0.3 |

Mold Shrinkage |

ASTM D955 |

mils/in |

3-6 |

3-6 |

3-6 |

3-6 |

Mechanical |

TEST METHOD |

UNITS |

DURAPLEX 30% |

DURAPLEX 70% |

DURAPLEX OPTIX SG05 (50%) |

DURAPLEX OPTIX SG10 (100%) |

|---|---|---|---|---|---|---|

Tensile Strength |

ASTM D638 |

psi |

9,000 |

7,100 |

8,000 |

5,600 |

Tensile Modulus of Elasticity |

ASTM D638 |

psi |

376,000 |

304,000 |

340,000 |

250,000 |

Flexural Strength |

ASTM D790 |

psi |

13,690 |

10,610 |

12,000 |

8,300 |

Izod Impact Strength – Molded Notch |

ASTM D256 |

ft-lb/in Notch |

0.6 |

0.9 |

0.7 |

1.1 |

Ball Drop Impact |

Pass |

Pass |

Pass |

Pass |

||

Rockwell Hardness |

ASTM D785 |

M-78 |

M-59 |

M-68 |

M-46 |

Thermal |

TEST METHOD |

UNITS |

DURAPLEX 30% |

DURAPLEX 70% |

DURAPLEX OPTIX SG05 (50%) |

DURAPLEX OPTIX SG10 (100%) |

|---|---|---|---|---|---|---|

Deflection Temperature @ 264 psi (1.8 MPa) |

ASTM D648 |

°F |

198 |

190 |

194 |

185 |

Coefficient of Thermal Expansion |

ASTM D696 |

in/in/°F |

3.5x10-5 |

4.5x10-5 |

4x10-5 |

5x10-5 |

Flammability (Burning Rate) |

ASTM D635 |

in/minute |

0.85 |

1.53 |

1.25 |

1.97 |

Flammability |

UL 94 |

HB |

HB |

HB |

HB |

|

Smoke Density Rating |

ASTM D2843 |

% |

5.2 |

11.5 |

8.5 |

16.5 |

Self-Ignition Temperature |

ASTM D1929 |

°F |

>850 |

>850 |

>850 |

>850 |

Download

**Applicable to the acrylic substrate

These suggestions and data are based on information we believe to be reliable. They are offered in good faith, but without guarantee, as conditions and methods of use are beyond our control. We recommend that the prospective user determine the suitability of our materials and suggestions before adopting them on a commercial scale.